| Name | Description | Technical data sheet |

EPO-TEK 920-FL |

Two component, high Tg, electrically insulating, thermally conductive epoxy designed for thermal management applications found in semiconductor, hybrid microelectronics, PCB, and optical industries. It is a low viscosity version of Epo-Tek® 920. | |

EPO-TEK 930-4 |

Two component, thermally conductive epoxy, formulated with a very fine boron-nitride filler particle. It is also available in a single component frozen syringe. | |

EPO-TEK H65-175MP

|

Single component, alumina-filled epoxy for military hybrid die and component attach. It can also be used for semiconductor and high temperature ceramic and vacuum packaging. | |

EPO-TEK H67MP |

Single component, thermally conductive epoxy for military hybrid die and component attach. It can also be used for semiconductor and high temperature ceramic and vacuum packaging. | |

EPO-TEK H70E |

Two component, thermally conductive, electrically insulating epoxy designed for chip bonding in microelectronic and optoelectronics applications. | |

EPO-TEK H70E-2 |

Two component, thermally conductive electrically insulating epoxy designed for glob-top chip protection in TAB and COB die-attach technologies. It is used to prevent chips from being mechanically damaged during micro-package assembly and handling. | |

EPO-TEK H74 |

Two component, thermally conductive epoxy designed for hybrid circuit assembly including die attach, substrate attach, lid-seal, heat dissipation, and hermetic sealing in general. | |

EPO-TEK H77 |

Two component, thermally conductive, electrically insulating epoxy system designed for lid-sealing of hybrids found in hermetic packaging of micro-electronics. Lids can be ceramic, glass, aluminum or kovar. Package types can be plastic, metal cases or ceramic. | |

EPO-TEK T7109EPO-TEK T7109-17 |

Two component, thermally conductive epoxy designed for die attach and heat-sinking applications found in the semiconductor, hybrid, medical and optical industries. | |

EPO-TEK T7110 |

Two component, thermally conductive, electrically insulating epoxy designed for heat sinking electronics and semiconductors. It may be used as an adhesive, potting, or encapsulation material, for industries such as consumer, medical or optics. | |

EPO-TEK T905-BN3 |

Thermally conductive, electrically insulating epoxy designed for heat sinking and encapsulation. | |

EPO-TEK TD1001 |

Single components, thermally conductive, electrically insulating epoxy designed for low stress semiconductor and electronics packaging. Low Tg, several weeks of pot-life and low modulus are a few of its traits. It is particularly suitable for bonding ferrite cores in power device plastic packaging. It guarentees an excellent adhesion to PCBs, ceramics, most metals and lead-frames. | |

EPO-TEK TV2001 |

Two components, thermally conductive, electrically insulating epoxy designed for low stress semiconductor and electronics packaging. Low Tg, moderate potlife, snap-curing and very low modulus are a few of its traits. It is particularly suitable for bonding ferrite cores in power device plastic packaging. It insures an excellent adhesion to PCBs, ceramics, most metals and lead-frames. It is also available in a frozen syringe. | |

| EPO-TEK TZ101 | Single component, electrically insulating, thermally conductive epoxy adhesive designed for heatsinking of semiconductors, hybrids, electronics, and optics. It is also available in a frozen syringe. |

01 Overview

Epoxy Technology’s thermally conductive line of epoxies are used extensively in many high-tech electronic applications. EPO-TEK products are unparalleled in their performance in effectively removing heat, providing increased dielectric strength and protecting circuits from hostile environments. Our epoxy adhesive properties can range from rigid (providing robust, thermally enhanced circuit protection) to flexible (ideal for substrates with significant CTE mismatches).

02 Product list

03 Complementary products

Volumetric valve

Revolution, the linear displacement valves from the series are the first MV valves incorporating a volumetric concept.

Viscotec-pharma & cosmetic

ViscoTec offers an ideal solution for high-precision and shear sensitive filling, conveying and metering of pharmaceuticals and fluids, from very liquid to highly viscous.

Valve without contact

The FCM100 is ideal for any low viscosity underfill, encapsulant, conformal coating, and micro dot or bead dispensing project.

Valve Controller SVC100

The SVC100 Valve Controller is a stand-alone controller used for the operation of SV series feeder screw valves

Valve Controller 700ETC

The 700ETC valve controller allows the dosing valves to be controlled manually (operator) or automated (machine).

THINKY SR 500

The SR500 allows to proceed to the immediate mixture of 500 grams of manufacturer dough to braze , without preliminary intervention.

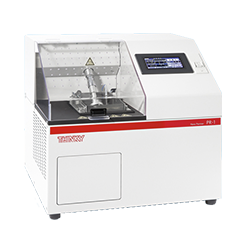

THINKY PR-1 Nano pre-mixer

The THINKY PR-1 Nano Pre-mixer for nanoparticle dispersion and deagglomeration of CNT, graphene and other 2D nanomaterials is a patented design using a unique dual ultrasonic system to uniformly disperse nanomaterials before mixing into other materials.

THINKY Nano pulverizer NP-100

NP-100 is a nano pulverising material at low temperatures that has a minimum of 100 mg and can be pulverised in a short time

THINKY ARV 930 TWIN

The ARV 930TWIN is the only mixer to be had a double platform of mixture. Its reservoirs coupled of 500ml each confer him a maximal capacity of a liter.

THINKY ARV 5000

The planetary mixer ARV 5000 is a large model that handles large capacity of maximum 3L and achieves deaeration at the submicron level.