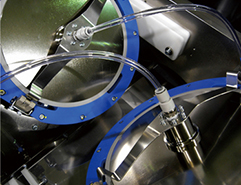

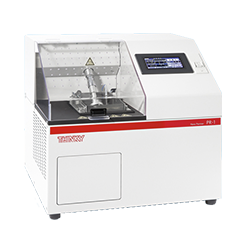

Designed to provide the equivalent mixing performance of the ARE-310 and ARV-310 laboratory models, the ARV-10kTWIN mixer features a vacuum pressure reduction system for the removal of submicron air bubbles. This mechanism provides deaeration at the submicron level which significantly reduces pressure and air release time.

In addition, it has a rotation / revolution ratio mechanism that supports the properties of the materials used in the program parameters.

This mixer helps to improve the mass production of new materials while improving the efficiency of production, the quality of materials and the profitability of your mass production lines.