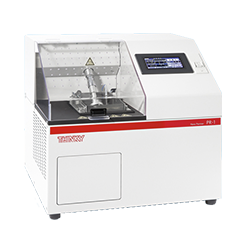

The SR500 can prepare uniform viscosity in a short time for solder paste just taken from cold storage without bringing it back to room temperature. Metal particles with high specific gravity, such as solder particles settle to the bottom of containers in cold storage, causes differences in material viscosity.

The SR 500 regulates the viscosity of solder paste in a short time, with uniform viscosity from top to bottom. Also, because it can remove air bubbles thought to cause spattering of solder balls, it contributes to reducing the defect rate.

The SR 500 can immediately prepare cold stored solder paste without bringing it back to room temperature. By optimizing the mixing recipe, viscosity preparation and temperature preparation for solder paste is easy. It also removes large air bubbles in the paste, which are considered the cause of solder paste defects. It handles commercial 500g solder paste containers. It restirs and redisperses solder paste that has been used. Finally, it supports solder paste in syringes by using the optional adapter.