EIT Microcure

EIT®’s MicroCure® measurement system is comprised of two separate stand-alone items; the data collection radiometer which is placed in the ultraviolet (UV) environment to be measured, and a DataReader which reads and displays the measurement results from the radiometer.

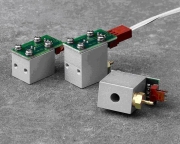

EIT Compact Sensor

This small, robust, stable sensor is highly resistant to solarization. Sensors have sealed optics to prevent fouling and an optional air/nitrogen purge to keep the sensor clean and cool. Sensors connect to all of EIT’s online monitoring electronics. A 0-10V and a 4-20 milliamp signal output is generated for each Compact Sensor when used with one of EIT’s conditioning units such as the Din Rail, MultiBrite or Online UV Intensity Display. These output signals can be interfaced to a PLC or other control system. Available in a choice of several UV bandwidths (A, B, C & V).

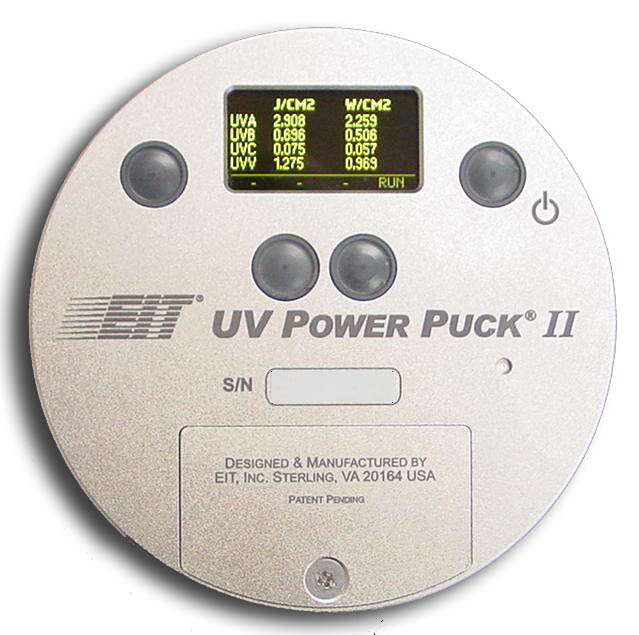

PowerPuck II Profiler

The “Profiler” versions of their Power Puck II and UviCure Plus II function as a standard Power Puck II or UviCure Plus II instrument while adding the ability to transfer the collected data and irradiance profile to a computer via a USB connector. The transferred data can be analyzed with EIT’s PowerView Software® II which allows the user to easily compare files to look at the conditions, lamp focus and lamp type. PowerView Software® II adds several new features including the ability to analyze a single UV band and data from four individual files in graph and data format, easily transfer screen shots for reports and the ability for users to add file information via a custom template.

EIT 3D Sensor

Quickly and easily profile dimensional and shaped objects of any size with EIT®’s 3DCure ™ Multi-Dimensional Measurement System. The system can produce up to 32 simultaneous measurements, which is perfect for setup and process verification of your UV lamp system. 3DCure ™ can be used with UV lamps mounted in a fixed bank or on a robotic arm. The collected exposure data (W/cm2 and J/cm2) for each sensor is displayed on your computer with the included Cure 3D™ software. The software supports ActiveX® controls and allows customization and export of the data into other programs. The use of ultra-violet curing on dimensional and shaped objects continues to grow. UV cured coatings offer several advantages over solvents and/or water-borne coatings pressed thermally or with IR. Line design, source placement and/or orientation, documentation of process limits and monitoring production conditions challenge users switching to UV curing tehnology. The 3DCure from EIT® addresses these challenges in a simple, flexible and easy to use measurement system. The UV irradiance (W/cm²) and energy density (J/cm²) arriving at multiple points on the cure surface can be easily and simultaneously measured.

EIT Powermap II

The UV PowerMAP® and UV MAP Plus™ measure UV irradiance, radiant energy density and temperature.