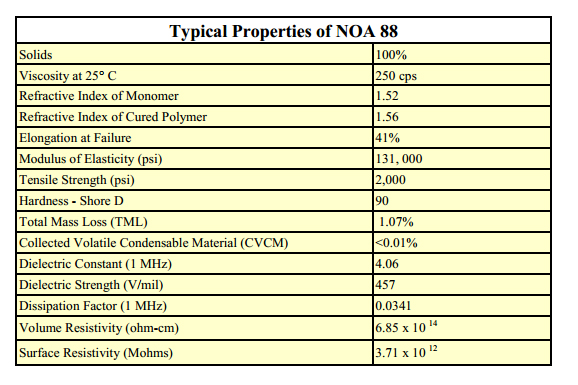

The adhesive is a one-part, 100% solid material that offers advantages in optical bonding applications. The use of NOA 88 eliminates premixing, drying, or heat curing operations common to other adhesive systems. Curing time can be regulated by the end user by varying the intensity of the curing source.

NOA 88 was formulated as a low outgassing (CVCM) and low Total Mass Loss (TML) adhesive. The ideal applications for this adhesive is for coating of parts destined for space exploration, bonding of high tech computer components, adhering parts in very sensitive instruments and coating sensitive components.

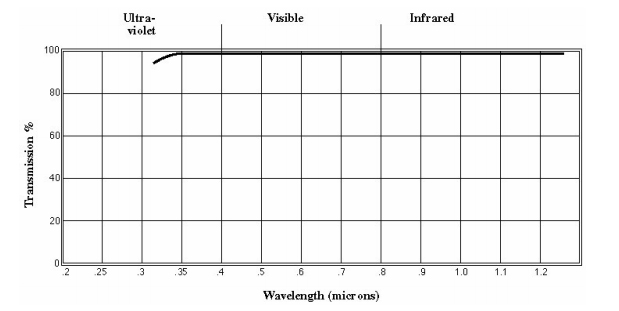

NOA 88 is cured by ultraviolet light (315nm to 400nm) with maximum sensitivity at 365nm. The adhesive requires 5 Joules/cm² of energy to fully cure a 25 to 50 micron bond. The material has low oxygen inhibition, so adhesive exposed to air will cure tack-free with sufficient exposure to UV light.

Curing of this adhesive can be performed in two steps: a short pre-cure to assure proper alignment of the parts, followed by the full cure. The entire bonding surface must be uniformly exposed to the long wavelength UV light when the material is being cured.

The pre-cure allows the user to align and set precision parts quickly without long holding times, and it minimizes the total number of fixtures. After the precure any excess adhesive can be removed from the parts using an solvent moistened cloth. Assemblies should be inspected at that time and rejected ones can be separated in Methylene Chloride. The bonded area must be soaked in the solvent and usually required an overnight soak.

When fully cured, NOA 88 has very good adhesion and solvent resistance, but has not reached its optimum adhesion to glass. This will come with aging over a period of about 1 week in which a chemical bond will form between the glass and adhesive. This optimum adhesion can also be obtained by aging at 50°C for 12 hours.

NOA 88 bonds can withstand temperatures of -15°C t o 60°C prior to aging and -60°C to 90°C after aging. In some cases the adhesive will withstand temperatures to 125°C when used as a film or coating, depending on the application.

The shelf life of the liquid material is at least four months from the shipment date if kept in a cool (5-22° C) dark place in the original container. If refrigerated, allow the adhesive to come to room temperature prior to use. Care should be taken in handling this material. Prolonged skin contact should be avoided and affected areas should be thoroughly washed with copious amounts of soap and water. If the adhesive gets into eyes, flush with water for 15 minutes and seek medical attention. Use the material in a well ventilated area, otherwise a NIOSH approved organic vapor mask is recommended.