- Home

- UV cured adhesives

- Acrylates

- Norland UV adhesives

- Electronic adhesives

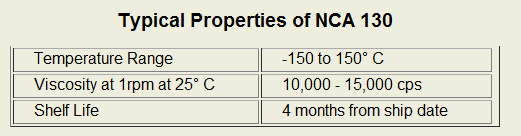

- Norland NEA 130

Norland NEA 130

Norland Conductive Adhesive 130 is a single component, silver filled, conductive adhesive for preventing static build up and will cure tack free to a tough, resilient polymer when exposed to ultraviolet light and heat. It is recommended as a fast and efficient way to tack, fill, seal or bond precision components or wires in place. With this system, a drop of adhesive is used to form a bridge between the component or wire, and the substrate. Exposure to UV light quickly tacks the component in place. Heat curing must be used to fully cure the adhesive. Useful applications for NCA 130 include wire tacking and bonding of head gimbal assemblies.

NCA 130 is sensitive to the whole range of UV light from 320 to 400 nanometers with peak sensitivity around 365nanometers. Cure time is dependent on light intensity and thickness of adhesive layer. The adhesive has been designed to be spot cured in small areas with and held or desk top UV light sources that are safe and easy to use. Stronger light sources can also be used that will cure faster. Recommended maximum thicknesses for curing with UV light is 3 mils.

In addition to the UV cure, NCA130 contains a latent heat catalyst that can cure areas that do not see the ultraviolet light. The heat catalyst allows the adhesive to cure in 360 minutes at 80°C, 60 minutes at 100° C, or 15 minutes at 125° C using a convection oven. Temperatures less than 80°C will not appreciably activate the adhesive. Recommended maximum thickness for heat curing is 10 mils. The heat cure will bring thicker layers of partially cured adhesive to full cure or provide the user with a choice when curing. In order to create the electrically conductive feature of the adhesive, the material must be heat cured.

NCA 130 has very good adhesion to glass, metals, printed circuit boards and many plastics. Since, the cure is very exothermic, the adhesive should be allowed to cool back to room temperature before adhesive testing begins.

To remove uncured adhesive from substrate use an acetone or alcohol moistened cloth. The cured adhesive can be removedby prying the drop with a knife edge or soaking in a solvent combinationof 90 parts methylene chloride and 10 part methanol.

Handling and Storage Precautions

CAUTION: Norland Conductive Adhesive 130 may cause skin irritation and prolonged contact with skin should be avoided. If contact occurs wash well with soap and water. Use in well ventilated area. Refer to the Material Safety Data Sheet for more information.

Store in a cool dark place (maximum temp30° C). CAUTION: Do not freeze material. Never expose the bulk material to high heat or ultraviolet light. It can generate an extremely exothermic reaction.