Silicones Greases and Compounds

Silicone based lubricants provide high performance and are more versatile than most materials available today. The unique properties inherent in the molecular backbone of silicone and oxygen contribute to silicone’s attractiveness where service requirements are extreme and/or where minimal maintenance attention is desired. Under many circumstances, silicone based products offer longer service life.

Typical Properties of Novagard Silicone Greases and Compounds include:

- Wide operating temperature ranges, -100°F to 400°F, higher in intermittent operation

- Ability to maintain viscosity, and/or consistency, without solidifying, smoking, melting or charring

- High oxidation resistance

- Good water washout resistance

- Excellent dielectric properties

- Noncorrosive, chemically inert, compatible with plastic and most organics

- Good release properties

- Excellent hydrolytic stability

Silicone Greases and Compounds offer:

- Excellent oxidation resistance and thermal stability

- Superior hydrolytic stability and water washout resistance

- Broad operating temperature range (−56°C to 204°C)

- Exceptional release properties and good lubricity

- Excellent dielectric properties, corrosion protection and viscosity stability

- Chemically inert and compatible with a wide range of substrates

| Rubber and Plastic Lubricants | Excellent resistance to moisture, corrosion and oxidation while exhibiting wide temperature ranges -55°C to 150°C. Conformance to SAE and Military specifications. |

| Dielectric Silicone Grease Compounds | Outstanding water repellence while hydrolytically stable with low toxicity. Wide temperature ranges of -57°C to 204°C. |

| NSF Standard 61 Lubricant Silicone Grease | Ideal for valve and O-ring lubrication with excellent vacuum capabilities and outstanding water resistance. Certified to NSF Standard 61 for Drinking Water System Components. |

| High Voltage Silicone Grease Compounds | Ideal for high voltage insulators to prevent flashover in addition to being an excellent dielectric and water repellent. Provides good adherence while chemically inactive with low toxicity. |

| Thermally Conductive Silicone Grease Compounds | Ideal for thermocouple wells, power diodes, transistors, semiconductors and ballasts. Excellent heat transfer compound for electrical and electronic industries, with outstanding long-term storage stability without oil separation. |

| Novagard® Versilube® Lubricants | These lithium soap thickened greases designed for metal to metal and non-metallic applications to reduce friction and wear under heavy loads, slow speeds, extreme temperature and variable environmental conditions. They are ideal lubricants for applications requiring extended service intervals. |

Generalities

Material Compatibility

Generally, silicone materials have the following impact on material properties:

Silicone Rubber – Tends to swell, soften and decrease in tensile strength.

Fluoro Rubber – No effect.

Organic Rubber – Slight shrinkage, hardening and loss of physical properties.

Plastic – No effect on polycarbonate, phenolic, polystyrene nylon, methacrylics or PTFE. Slight

swelling or shrinkage may occur in polyacetal, polyethylene, polypropylene or PVC.

Methods of Application

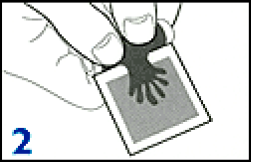

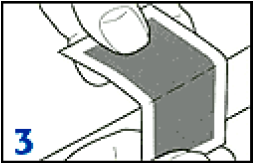

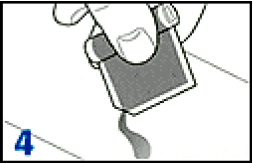

Silicone greases and compounds may be wiped on, brushed on, dispensed from a grease gun or applied by automated equipment. In addition, when dispersed in a non-polar solvent they may be applied by brushing, spraying or dip coating. Caution is required in the selection of solvents.

Handling and Safety

Material Safety Data sheets are available upon request from Novagard Solutions.

Cleanup of silicone greases and compounds can be accomplished using non-polar solvents such as mineral spirits. They are soluble in stoddard solvent, toluene and xylene. Caution should be observed whenever handling solvents.

Silicone greases are not suitable for use in contact with high concentrations of oxygen or highly oxidative materials. Contact with high pressure oxygen, ozone, peroxides or fuming nitric acid can result in fire or explosion. Silicone materials are damaged by exposure to strong mineral acids (e.g. sulfuric, hydrochloric, nitric), strong alkaline (e.g. sodium or potassium hydroxides), nitrates or peroxides.