Low Outgassing Adhesives

What Is Outgassing?

Outgassing is a measure of the level of residual low molecular weight species (including water if the material is not conditioned in a low moisture environment prior to testing) that can be evolved at elevated temperatures.

How Is It Measured?

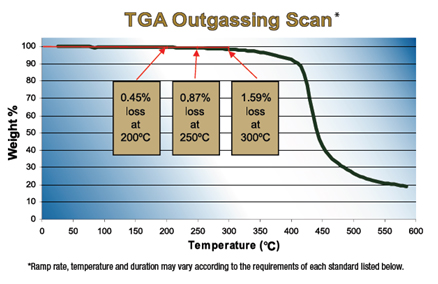

One method for measuring levels of outgassing is Thermal Gravimetric Analysis or TGA. This technique measures very small weight changes in a material as a function of temperature. The resultant percent weight versus temperature curve is then used to determine the weight loss or outgassing at specific temperatures.

Below is an example of a typical weight loss vs. temperature scan.

What Are The Standards?

NASA ASTM E595

Products that meet the NASA outgassing requirements must exhibit less than 1.0% Total Mass Loss (TML) after being exposed to 125°C for 24 hours in a vacuum. They must also contribute less than 0.1% Collected Volatile Condensable Materials (CVCM) during this exposure.

MIL-STD 883/5011

For military applications, products must produce 1.0% or less outgassing when exposed to 200°C in order to pass MIL-STD 883 Method 5011. Epoxy Technology is an approved DSCC testing facility for this standard.

Telcordia GR-1221

The fiber optic industry goes by many names including: photonics, telecommunications or optical components. There are many testing requirements within this industry. Epoxy Technology adhesives have been tested in accordance with Telcordia (formerly Bellcore) Standard GR-1221, “Generic Reliability Assurance Requirement for Passive Optical Components”. This testing helps to assure the practical, useful life for certain manufactured devices relating to long term (25 year) performance. For this test, the cured adhesive is heated from 50°C to 150°C at 5°C/minute in the TGA. A 0.1% weight loss for heat cured systems and a 0.25% weight loss for UV cured systems is considered evidence of a properly cured system and meets the test requirements. Below is a listing of EPO-TEK products that have met or exceeded this standard.