About Us

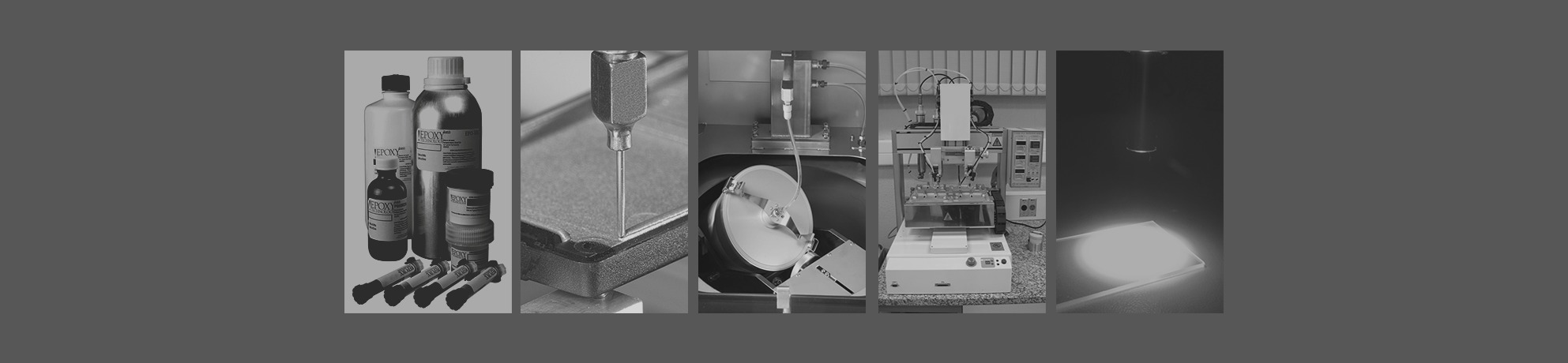

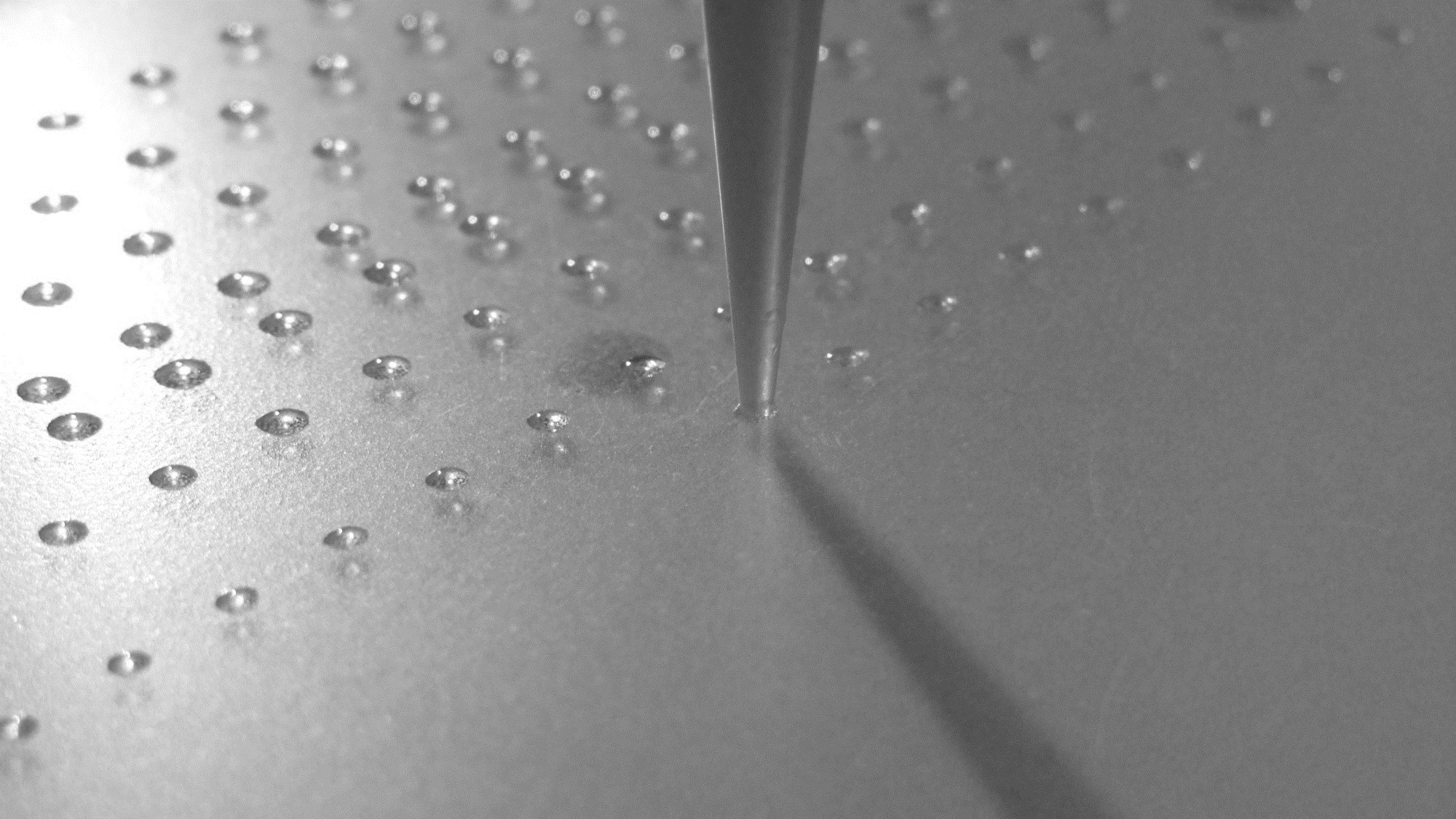

Member of Meridian Adhesives Group, the company Epoxy Technology Europe SRL (formerly known as Gentec Benelux) is a solutions provider addressing problems related to precision assembly, adhesives, encapsulants, coatings, UV curing and UV light measurement for a wide range of industries. With over 20 years of experience, Epoxy Technology Europe SRL is supplying quality equipment and materials to an ever growing number of industrial clients in Belgium, The Netherlands and Luxembourg.