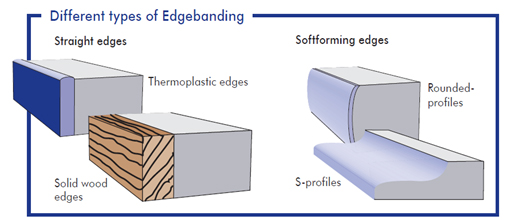

Edge Banding

In the edge banding field, the adhesive requirements of the furniture industry are constantly increasing, especially regarding faster application, temperature and heat resistance, shapes and materials. Suitable adhesive systems for edge banding are :

- EVA Hot Melts

- PO Hot Melts (Ethylene-vinyl acetate and polyolefin) :

- Reactive PUR Hot Melts (polyurethane) :

– Besides the physical setting there is a chemical cross linking

– Much higher temperature and moisture resistance from -40°C up to 140°C