Electrically & Thermally Conductive

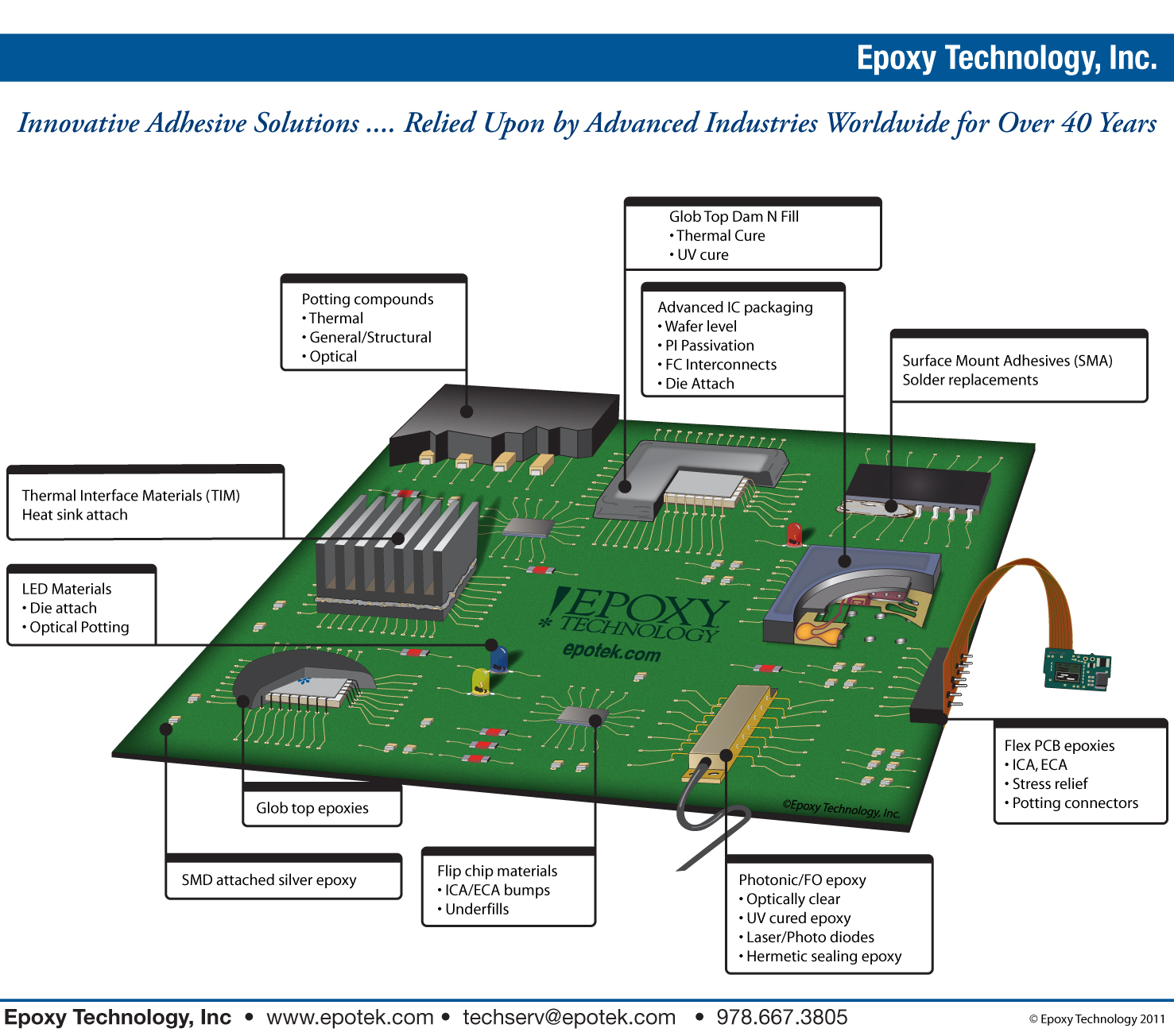

Epoxy Technology offers a full range of electrically and thermally conductive epoxy adhesives for the semiconductor, optoelectronic, automotive, aerospace and electronic assembly industries. Our extensive product line allows users to easily select the optimal adhesive for their specific application; based on the bescombination of physical, electrical and mechanical characteristics.

EPO-TEK electrically conductive epoxies have been used successfully for over 35 years in a wide variety of applications including: IC packaging, hybrid microelectronics and circuit assembly as well as today in solar cell assembly, LEDs and high power management.

Representative examples :

- Epo-Tek® H20E is a two components, 100% solid silver-filled epoxy system designed specifically for chip bonding in microelectronic and optoelectronic applications. It is also used extensively for thermal management applications due to its high thermal conductivity. It has proven itself to be extremely reliable over many years of service and is still the conductive adhesive of choice for new applications. It is also available in a single components frozen syringe.Epoxy Technology’s Epo-Tek® H20E has been used successfully for over 35 years in a wide variety of applications including LED, solar, high power management and HDD applications.

- EPO-TEK® EK1000 – a new generation, single component ECA with exceptional thermal conductivity for high power applications with a thermal conductivity value ranging from 12.6 to 22.0 W/m°K.

- EPO-TEK® EJ2189 – a new generation, two component ECA designed for low temperature curing from 23°C (ambient) to 80°C that exhibits superior adhesion to a wide variety of substrates including most metals, ceramics, glass and plastics.

- EPO-TEK®E2101 is a two component, thixotropic, electrically conductive adhesive. It may be used for circuit assembly and semiconductor applications.

- EPO-TEK® E3001-HV is a snap cure, single component, silver-filled die attach adhesive for semiconductor plastic IC packaging. It is also available in a frozen syringe.

- EPO-TEK®E3082 is a single component, silver filled, electrically and thermally conductive adhesive for semiconductor die attach, hybrid, electronics and optical applications. It is a one component version of EPO-TEK®E2082.

- EPO-TEK®E4110 is an electrically conductive, silver-filled epoxy paste. This two component system is designed for low temperature curing from ambient to 80°C, although other heat cures can be used.

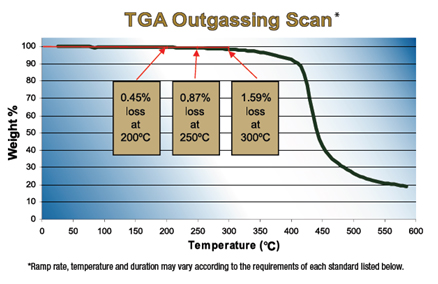

- EPO-TEK®ED 1003 is a single component, electrically conductive adhesive designed for high power LED die attach applications. Its combination of high thermal conductivity, shiny silver appearance and low outgassing are ideal for the demanding requirements of high brightness LED’s. Other features include a long potlife, low viscosity and high thixotropic index making it suitable for a wide range of application methods wafer level stamping and syringe dispensing.

- EPO-TEK®ED1021 is a single component, silver-filled epoxy designed for low power semiconductor LED die attach applications. Unique features include its ability to achieve high thermal conductivity values at low cure temperatures and a very shiny silver appearance which enhances overall LED brightness. Other benefits include long pot-life, low viscosity and high thixotropymakng it ideal for wafer level tamping as well as syringe dispensing.

- EPO-TEK® EJ2189-LV is a low viscosity, two-component, room temperature curing conductive epoxy.

- Epo-Tek® EK 1000 is a single components, silver-filled adhesive that exhibits exceptional thermal and electrical conductivity along with a shiny silver appearance making it ideal for the demanding requirements of high power LED die attach applications. Other benefits include low viscosity and high thixotropy making it suitable for a wide range of application techniques.

- EPO-TEK®EM127 is a single component, heat curable, electrically conductive epoxy adhesive for semiconductor IC and LED die attach applications.

- EPO-TEK®H20E-PFC is a two component, semiconductor grade epoxy, designed for flip chip interconnects using a solder-free joining method.

- EPO-TEK® H20S is a modified version of EPO-TEK®H20E, designed primarily for die stamping and dispensing techniques for chip bonding. EPO-TEK®H20S is a highly reliable, two component, silver-filled epoxy with a smooth, thixotropic consistency. In addition to the high electrical conductivity, the short curing cycles, the proven reliability, and the convenient mix ratio, EPO-TEK® H20S is extremely simple to use.

- EPO-TEK®H31 is a single component, silver-filled, electrically conductive epoxy designed for semiconductor die attach applications found in hybrids, JEDEC, and opto-electronic packaging.

- EPO-TEK®H35-175MP is a single component, silver-filled epoxy for military hybrid die and component attach.

- EPO-TEK®H37-MP is a single component, electrically conductive, thixotropic silver-filled adhesive for die-attach and SMD attach inside hybrid microelectronic packages. It is also available in a frozen syringe.